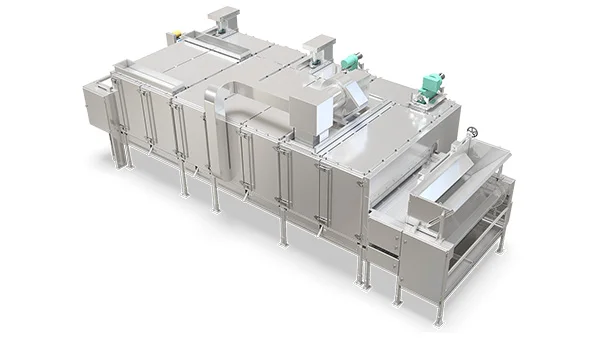

The Single Conveyor Dryer/Cooler offered by Wolverine Proctor is the most widely used continuous dryer in the world, and for a good reason. It’s the result of years of production experience, bringing together carefully selected fans, heating systems, conveyors, chain, panels, and other equipment to meet your production needs.

Advantages

Whether it is a 0.6 meter (two foot) wide unit drying an expensive pharmaceutical product or a 4.4 meter (14-foot, 6-inch)-wide machine producing product at a rate of 45,360 kilograms (100,000 pounds) per shift, you can rely on the Single Conveyor Dryer/Cooler for maximum efficiency at each point of your heating and drying process.

Standard Features

Self-supporting, segmented, positively driven conveyors are supplied with perforations designed to minimize sifting and increase time between cleanings

Integral guards positively contain the product, minimizing loss while maintaining proper airflow through the product

The conveyor returns outside the drying chamber for ease of cleaning. Integral coolers, if required, stop the drying or roasting process very quickly and discharge products at close to ambient temperatures

Preassembly in Wolverine Proctor’s workshops assures ease of field assembly and minimizes installation time

Lower-cost minimal pre-assembly shipments can also be supplied to reduce costs for individual country and shipping requirements

Explore This Product

Maximum Uniformity

Highest thermal efficiency and gentle drying conditions, preventing product degradation.

Minimal Loss

Integral guards positively contain the product, reducing loss.

Easy Maintenance

The conveyor returns outside the drying chamber for easy cleaning.

Temperature Control

Systems range from simple on-off indicating controls to the most sophisticated menu-driven programmable logic control instruments for the dryer and other units.

Flexible

Use up or down airflow (or both).

Fast Installation

Pre-assembled at Wolverine Proctor to shorten install time.

Features

Robust and flexible for your drying and cooling needs

Regardless of what you’re processing, this dryer/cooler will help you hit maximum efficiency at every point of your production.

Trusted by customers in over 100 countries, more than 10,000 units of our equipment are currently operating worldwide. We continue to deliver reliable equipment across diverse industries, including food, fiber, tobacco, chemicals and other specialized sectors.

Consult Now